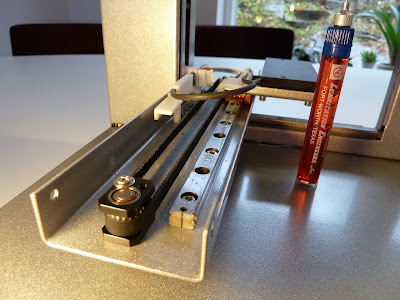

My UP! started screaming and squeeking after about 1½ spool, especially the upper (X axis?) linear rail. It also made the whole machine resonate and vibrate so I thought that lubing up the rails and bearing would be a good idea.

My UP! started screaming and squeeking after 1½ spool, especially the upper (X?) linear rail. It also made the whole machine resonate and vibrate so I thought that lubing up the rails and bearing would be a great idea.

It was also a good excuse to see what hides beneath the covers, I've had the machine a few weeks without taking it apart, that must be a record.

Anyway, to open it you need to remove the bottom first, or at least it´s easier to remove the front cover then. There are four screws around it, all the same length and size so don't have to remember exactly where they belong. Remove all the "loose" stuff first, like the extruder, spool holder and filament feeder so that you wont hurt them in the process. Here is some photos from the adventure.

I used some ball bearing oil for the ball bearings but also for the rails. I´m sure there is a better oil for this, a more low viscosity oil I assume but this worked good too. |

|

Here are all the stepper drivers and electronics. The fan is a little bit loud, so my next project would be to fit a quieter one (or two maybe to maintain the airflow). |

Yes! It is almost quiet now, I didnt think it would be such a difference.

I put the oil in all bearings and rails . Change a lot do more better prints I need to solution my platform and the curling also to day buy a acrylic to prof a new experience but we need to control our temperature in the head and in the platform .

ReplyDeleteChris.E thanks , I go better when I saw your work and you big ideas .

J